This is a dough made with yeast, flour, water, table margarine, salt, sugar, and an improver. The dough is well-kneaded, homogenized, plastic, and cooler than typical yeast dough. The temperature of the margarine and the dough should be approximately the same. The temperatures should range between 15 and 20°C. The dough should rest for at least 15 minutes, which improves its physical properties.

Mixing the dough: 3 minutes slow + 4 minutes fast

Resting the dough on the table: 15–20 minutes

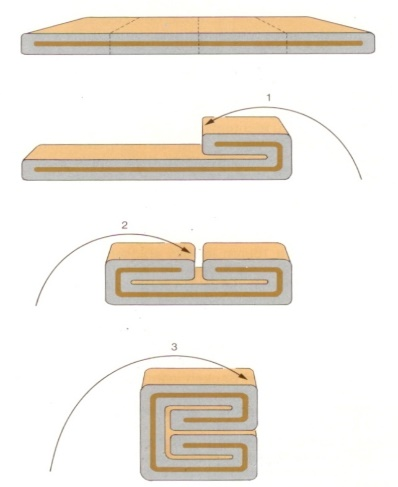

Folding the dough: depending on the type of product and amount of margarine: 3×3 (27 layers) or 2×4 (16 layers) – rest in the fridge for 35 minutes

Proofing time in the proofer: 40–45 minutes

Baking temperature: 200 to 210°C

Baking time: 10–12 minutes

Procedure:

All ingredients and cold water are mixed in a mixer (some of the water can be replaced with ice flakes). The consistency of the dough must always be adapted to the consistency of the margarine. Soft margarine tends to “leak” from the dough, while hard margarine stretches the dough and does not compress – it fails to create an even fat layer and can tear the dough.

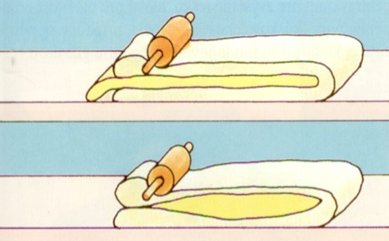

The finished dough is divided into the desired loaves and left to rest for 15 minutes on the work surface, covered with a clean cloth to prevent a skin from forming on the surface. After resting, the dough is shaped into a square and the laminating margarine is wrapped inside.

This method is used when we want the product to have smaller pores.

The dough is rolled out using a sheeter to a thickness of 10–9 mm and folded in thirds. Then, the dough is rotated 90° and the rolling and folding process is repeated. Finally, the dough is rotated 90° once more, rolled out again, and folded in thirds. This results in 27 layers (3×3). The dough is then wrapped in plastic wrap and placed in the refrigerator to rest for 35 minutes.

This method is used when we want the product to have larger pores – such as for croissants.

The dough is rolled out using a sheeter to a thickness of 10–9 mm and folded in four. Then, the dough is rotated 90° and the process is repeated. The dough is wrapped in plastic wrap and placed in the refrigerator to rest for 35 minutes.

After completing all the steps, the dough is ready for final rolling and shaping. Once the products are shaped, they are placed in the proofer for 40–45 minutes. After proofing, the product is brushed with egg wash (if needed) and placed in the oven.

© 2025 – Beluša Foods s. r. o. | CREA:THINK STUDIO | All rights reserved